While we as the designers and manufacturers of our products could choose any size transformer we wished, that certainly wasn't the case for others who had already made their choices and now their products were out in the marketplace.

This brings us back to the problem I was facing in the late 1990s when I hoped to come up with a way of improving power supply performance of products not our own.

Would it be possible to externally increase the size of an internal power transformer? And if we could, how about those power supply capacitors inside? Any chance of adding more capacitors without opening the case?

Seemed at the time like more of a fairy tale than possible, but…

While we as the designers and manufacturers of our products could choose any size transformer we wished, that certainly wasn't the case for others who had already made their choices and now their products were out in the marketplace.

This brings us back to the problem I was facing in the late 1990s when I hoped to come up with a way of improving power supply performance of products not our own.

Would it be possible to externally increase the size of an internal power transformer? And if we could, how about those power supply capacitors inside? Any chance of adding more capacitors without opening the case?

Seemed at the time like more of a fairy tale than possible, but…

External cures

by Paul McGowan

From as early as 1980 it had been clear to us that the bigger the power transformer the better the sound—a fact that at first didn't make a whole lot of sense.

Why would a preamplifier that consumed no more than a few watts benefit from a power transformer capable of 100 times that?

Impedance.

Turns out that because bigger power transformers have thicker wire they have lower impedance, thus less modulation.

An easy way of visualizing the difference between high and low impedance transformers would be something akin to spongy vs. brick wall. A spongy power transformer is malleable by the load—or in our case, modulated by the music. A bigger transformer is less affected and thus is impervious to being pushed around by the amplifier's circuit.

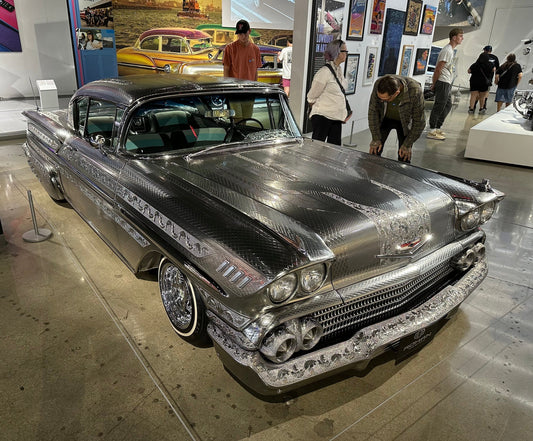

Once we recognized the importance of the power transformer we began implementing bigger and bigger ones until they no longer fit into the chassis, prompting us to begin offering external add-on transformers. Here's one of the first we ever produced:

While we as the designers and manufacturers of our products could choose any size transformer we wished, that certainly wasn't the case for others who had already made their choices and now their products were out in the marketplace.

This brings us back to the problem I was facing in the late 1990s when I hoped to come up with a way of improving power supply performance of products not our own.

Would it be possible to externally increase the size of an internal power transformer? And if we could, how about those power supply capacitors inside? Any chance of adding more capacitors without opening the case?

Seemed at the time like more of a fairy tale than possible, but…

While we as the designers and manufacturers of our products could choose any size transformer we wished, that certainly wasn't the case for others who had already made their choices and now their products were out in the marketplace.

This brings us back to the problem I was facing in the late 1990s when I hoped to come up with a way of improving power supply performance of products not our own.

Would it be possible to externally increase the size of an internal power transformer? And if we could, how about those power supply capacitors inside? Any chance of adding more capacitors without opening the case?

Seemed at the time like more of a fairy tale than possible, but…

While we as the designers and manufacturers of our products could choose any size transformer we wished, that certainly wasn't the case for others who had already made their choices and now their products were out in the marketplace.

This brings us back to the problem I was facing in the late 1990s when I hoped to come up with a way of improving power supply performance of products not our own.

Would it be possible to externally increase the size of an internal power transformer? And if we could, how about those power supply capacitors inside? Any chance of adding more capacitors without opening the case?

Seemed at the time like more of a fairy tale than possible, but…

While we as the designers and manufacturers of our products could choose any size transformer we wished, that certainly wasn't the case for others who had already made their choices and now their products were out in the marketplace.

This brings us back to the problem I was facing in the late 1990s when I hoped to come up with a way of improving power supply performance of products not our own.

Would it be possible to externally increase the size of an internal power transformer? And if we could, how about those power supply capacitors inside? Any chance of adding more capacitors without opening the case?

Seemed at the time like more of a fairy tale than possible, but…

- Choosing a selection results in a full page refresh.

- Opens in a new window.