Editor’s Note: Chris Brunhaver is the senior speaker design engineer at PS Audio. We asked him about what inspired him to become involved in the audio industry.

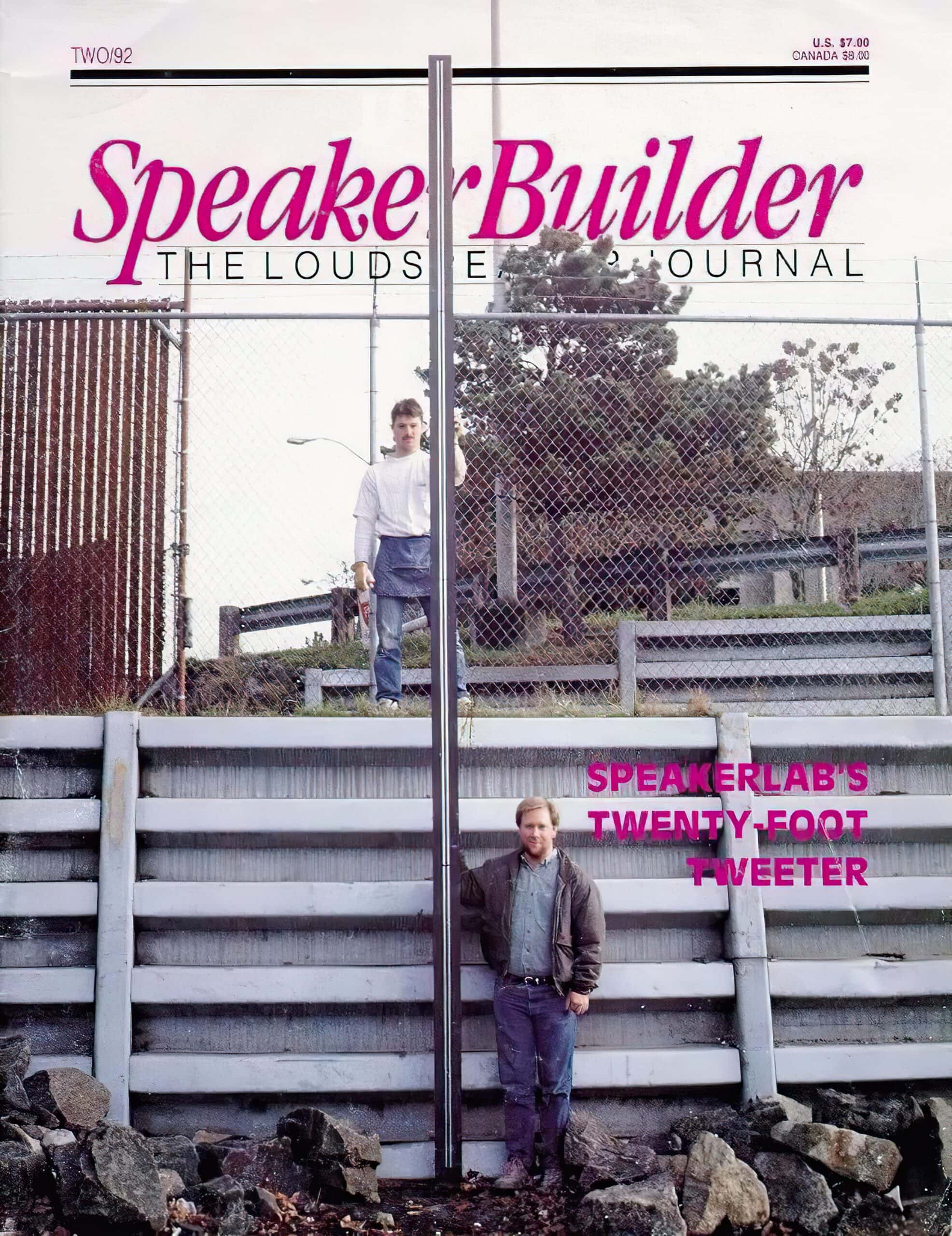

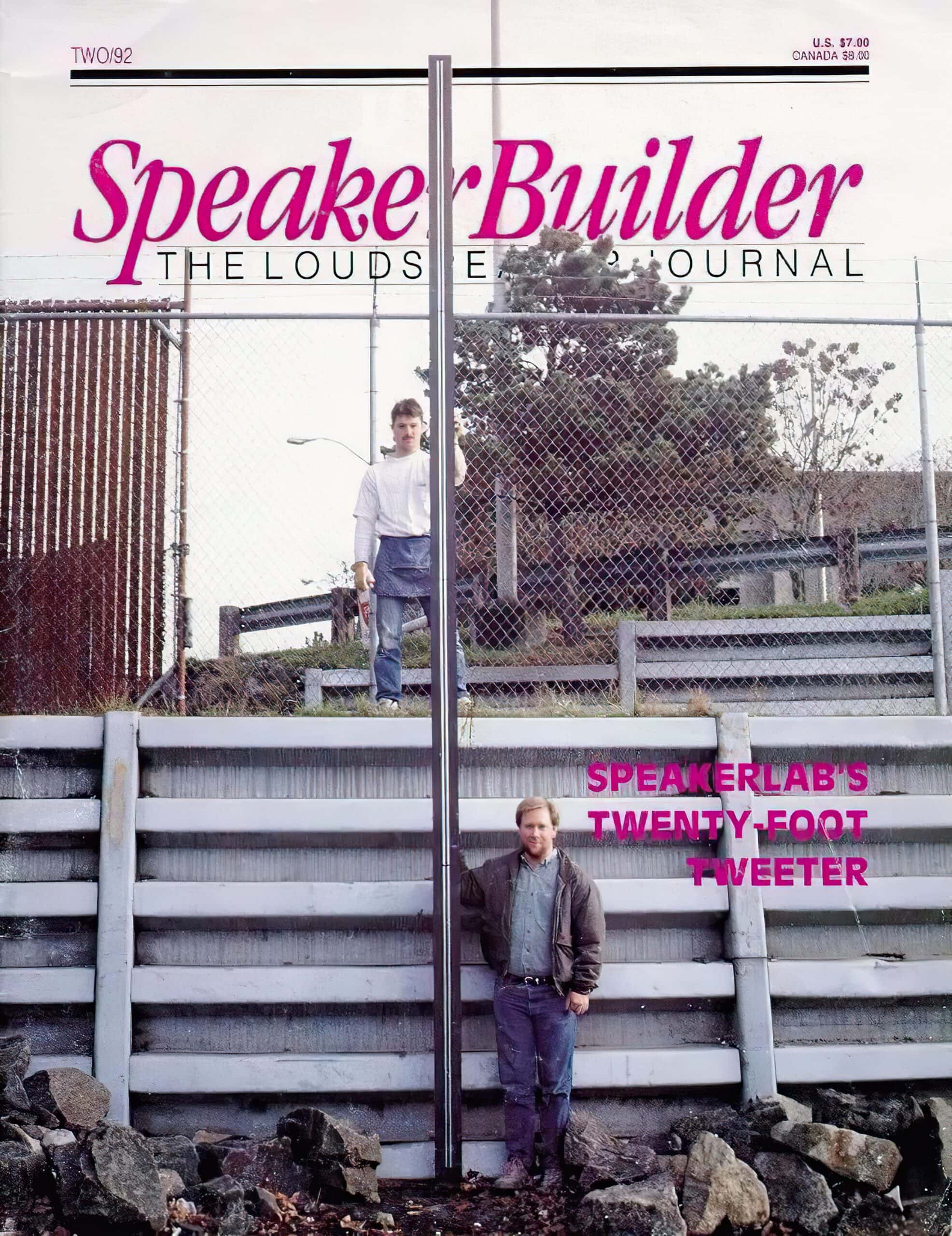

On a typical dreary, overcast day in the funky and artsy Fremont neighborhood of Seattle, a pair of men stood outside a warehouse with a long, relatively thin metal plank in their hands. It was twenty-one feet long and about five inches wide. It was being held upright for a photo, rather cavalierly considering its $50,000 value, with one of the fellows standing atop a vertical embankment about ten feet up in order to hold the upper half.

Upon closer inspection, you could see a glint of silver running down the middle, a clue to its function.

This photo was later published as the cover photo of a hobbyist magazine called

Speaker Builder (now

AudioXpress) for the publication’s second issue of 1992. The headline on the cover read, “Speakerlab’s 20-foot Tweeter.”

Yes, this massive unwieldy thing was made to produce sound! It was made by a small, Seattle-based loudspeaker company, Speakerlab, for a research project on behalf of Boeing’s commercial airplane division. Boeing needed an acoustic line source – a speaker where the wave front of the sound propagates more in the shape of a cylinder rather than in the spherical shape of a traditional point source speaker (as the name suggests, a speaker that produces sound from a single point, or from components that are acoustically “small”).

Highly directional along its length, this kind of line source design can offer some unique acoustical properties and advantages, such as minimizing certain interactions with a room, increasing speech intelligibility, and halving the drop in sound pressure over a given distance. This giant tweeter was actually being used by Boeing for acoustic aerofoil (wing) research.

This “tweeter” was actually a wideband push-pull planar magnetic speaker that covered the human vocal range and beyond. It used a very thin membrane of plastic with conductive traces, with the traces laid on the membrane like pinstriping on a car. The membrane, which functioned as the speaker’s diaphragm, was placed between magnets of different polarities. When an electrical signal was fed to the diaphragm, it was alternately attracted and repelled by the magnets, causing the diaphragm to move back and forth and produce sound.

This wasn’t a new concept at the time – it was generally similar to some of the Infinity and

Magnepan (Magneplanar) designs, but with some important construction differences to make it usable to over a wider frequency range, with higher output and with a line source-type of sound coverage.

Feel the quality! PS Audio's Paul McGowan and the Infinity IRS loudspeaker system.

This particular device was the brainchild of David Graebener, the engineer of the 20-foot behemoth and one of the founders of Speakerlab. He had previously worked with Bob Carver in developing Carver’s Amazing Loudspeaker, which incorporated a rather similar concept that he wanted to further improve. The Boeing project served to fund that development and the custom-made pneumatic tensioning and assembly jigs that were required to build the huge device.

These jigs were cleverly made in three separate pieces that could be lined up to make the giant Boeing unit, or separated into three pieces to make individual units up to six feet in length, which Speakerlab had actually used to make a short-lived product named the Auricle. However, during this time Speakerlab had been downsizing from being a manufacturer into becoming a retail shop, and couldn’t support the further development of this product and keep David on as a full-time engineer. David later went on to co-found speaker company Bohlender Graebener (BG) and do work with Harman, Eastech,

Wisdom Audio and American Technology Corporation and, in the process, becoming one of the foremost experts in planar magnetic speaker technology.

My part in this story is that one of the men shown in the magazine article and on the other side of the camera from that giant tweeter on the

Speaker Builder cover was my father, Richard “Skip” Brunhaver, who owned Speakerlab for many years and was a physics major, navy pilot, and polymath. I was just 13 years old at the time of the 20-foot tweeter project, but growing up with a family audio business since age five has led me to a lifelong pursuit of loudspeaker design and a love of music.

To further close the loop, one of the main customers of the smaller, later production versions of this driver technology (both the Carver and Bohlender Graebener versions) was Genesis Loudspeakers, founded by Paul McGowan of PS Audio and Arnie Nudell of Infinity. Genesis implemented the driver in some ultra-high-end designs including the Genesis 1, II.5 and others.

The Genesis II.5 loudspeaker.

I worked as an engineer at Bohlender Graebener starting at the age of 26, for five years from 2005 – 2010. Although the company had developed newer, lighter and more efficient versions, through the use of photo-etched diaphragms and rare earth magnets, BG was also still using the same assembly jigs that my father and David had developed for Speakerlab that had been used to build the 20-foot tweeter. The assembly jigs had continued to be used to produce those older line source models until 2013, when the company was acquired by Christie Digital in order to use the technology as the underpinnings of their cinema speaker line.

I now work as the senior speaker design engineer at PS Audio. We’re currently working on a new speaker, the FR-30, as the first of an entire high-end loudspeaker line utilizing our using custom planar magnetic driver technology at its core. That big ol’ tweeter has an even bigger place in my heart, and is much of the reason that I’m where I am today.

Exploded diagram of a Bohlender Graebener NEO10 driver, a descendant of the 20-Foot Tweeter.

Yes, this massive unwieldy thing was made to produce sound! It was made by a small, Seattle-based loudspeaker company, Speakerlab, for a research project on behalf of Boeing’s commercial airplane division. Boeing needed an acoustic line source – a speaker where the wave front of the sound propagates more in the shape of a cylinder rather than in the spherical shape of a traditional point source speaker (as the name suggests, a speaker that produces sound from a single point, or from components that are acoustically “small”).

Yes, this massive unwieldy thing was made to produce sound! It was made by a small, Seattle-based loudspeaker company, Speakerlab, for a research project on behalf of Boeing’s commercial airplane division. Boeing needed an acoustic line source – a speaker where the wave front of the sound propagates more in the shape of a cylinder rather than in the spherical shape of a traditional point source speaker (as the name suggests, a speaker that produces sound from a single point, or from components that are acoustically “small”).

Highly directional along its length, this kind of line source design can offer some unique acoustical properties and advantages, such as minimizing certain interactions with a room, increasing speech intelligibility, and halving the drop in sound pressure over a given distance. This giant tweeter was actually being used by Boeing for acoustic aerofoil (wing) research.

This “tweeter” was actually a wideband push-pull planar magnetic speaker that covered the human vocal range and beyond. It used a very thin membrane of plastic with conductive traces, with the traces laid on the membrane like pinstriping on a car. The membrane, which functioned as the speaker’s diaphragm, was placed between magnets of different polarities. When an electrical signal was fed to the diaphragm, it was alternately attracted and repelled by the magnets, causing the diaphragm to move back and forth and produce sound.

This wasn’t a new concept at the time – it was generally similar to some of the Infinity and Magnepan (Magneplanar) designs, but with some important construction differences to make it usable to over a wider frequency range, with higher output and with a line source-type of sound coverage.

Highly directional along its length, this kind of line source design can offer some unique acoustical properties and advantages, such as minimizing certain interactions with a room, increasing speech intelligibility, and halving the drop in sound pressure over a given distance. This giant tweeter was actually being used by Boeing for acoustic aerofoil (wing) research.

This “tweeter” was actually a wideband push-pull planar magnetic speaker that covered the human vocal range and beyond. It used a very thin membrane of plastic with conductive traces, with the traces laid on the membrane like pinstriping on a car. The membrane, which functioned as the speaker’s diaphragm, was placed between magnets of different polarities. When an electrical signal was fed to the diaphragm, it was alternately attracted and repelled by the magnets, causing the diaphragm to move back and forth and produce sound.

This wasn’t a new concept at the time – it was generally similar to some of the Infinity and Magnepan (Magneplanar) designs, but with some important construction differences to make it usable to over a wider frequency range, with higher output and with a line source-type of sound coverage.

Feel the quality! PS Audio's Paul McGowan and the Infinity IRS loudspeaker system.

Feel the quality! PS Audio's Paul McGowan and the Infinity IRS loudspeaker system. The Genesis II.5 loudspeaker.

The Genesis II.5 loudspeaker. Exploded diagram of a Bohlender Graebener NEO10 driver, a descendant of the 20-Foot Tweeter.

Exploded diagram of a Bohlender Graebener NEO10 driver, a descendant of the 20-Foot Tweeter.

0 comments